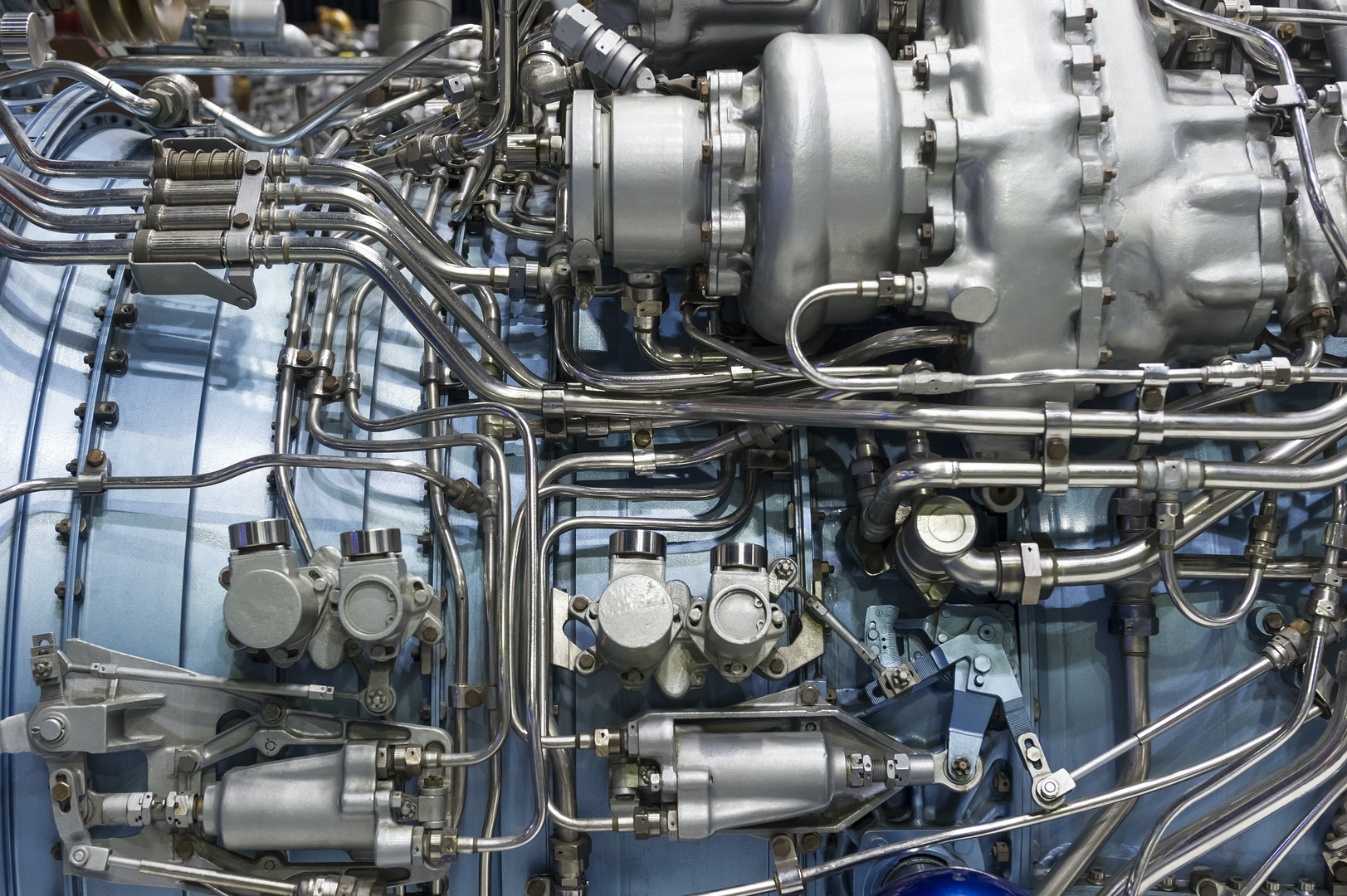

Industries

Our tube benders have a very wide range of applications that will suit any industry, from bending simple, single bends in single planes to very complex bending using CNC tube benders. We look for the machine that will solve your particular application needs, keeping your budget in mind.

Horn Machine Tools provides the perfect solution to fit your company’s tube bender needs

Manufacturers through North America rely on HMT tube bending machines to perform the most difficult and demanding applications in their respective industries. This is why HMT is the most trusted supplier of tube bending equipment. HMT offers simplicity for the operator, easy maintenance, and reliable service. No matter the industry, no matter the job, no matter the challenge, Horn Machine Tools provides the world’s greatest tube bending machines.