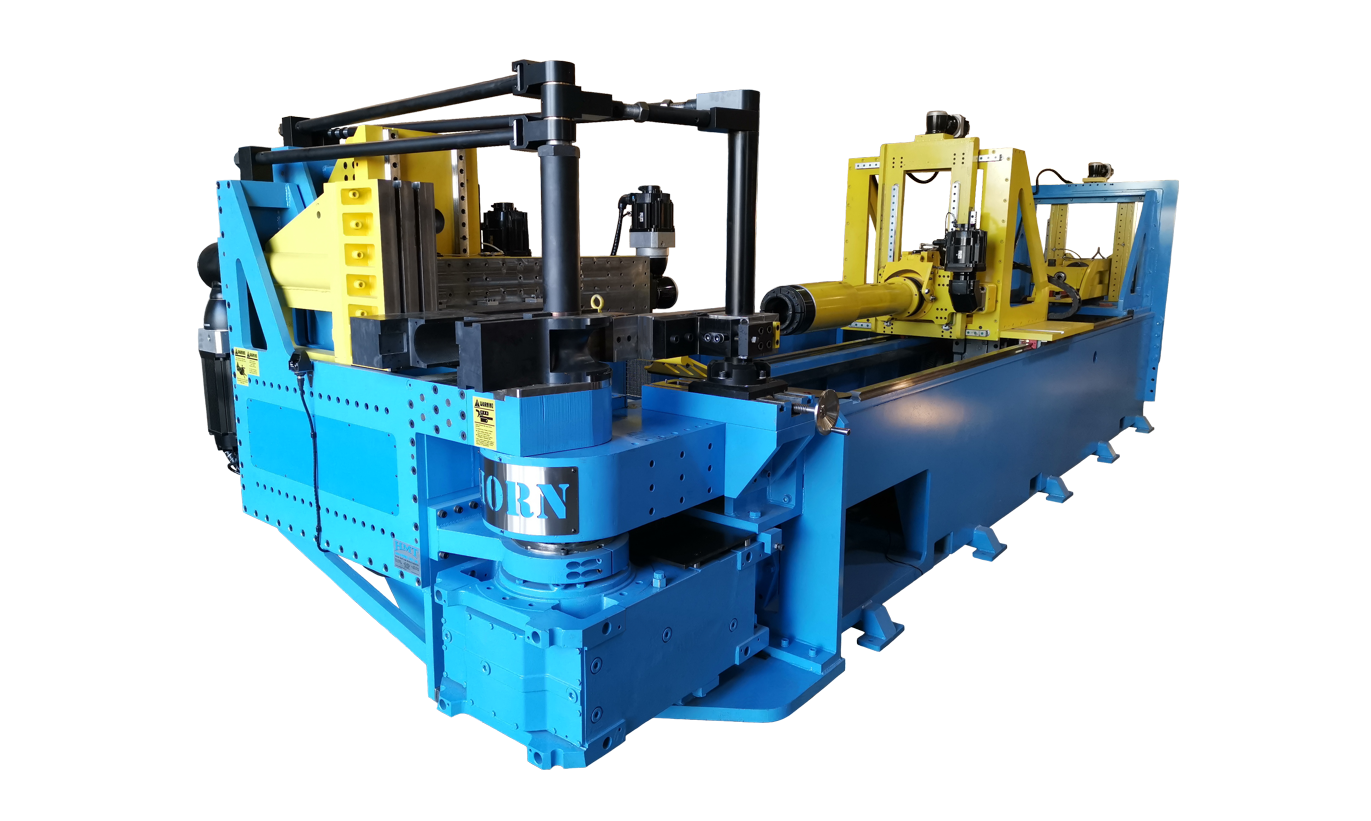

HMT 6.0ECNC-MS

All-electric Multi-stack CNC Tube Bender

HMT 6.0ECNC-MS

HMT’s 6.0ECNC-MS bender is the largest multi-stack CNC bender that HMT provides. The frame increases in size and the gear ratios and the KW of the servo motors increase as well in order to develop the necessary torque to bend 6″OD stainless with tight radius requirements. Some manufacturers shift the entire bend head when changing stacks on a 6″ machine and this causes long cycle times to occur on multiple bend parts. HMT’s unibody construction allows for fast and efficient stack shifting on the 6.0ECNC-MS as only the tube is shifted vertically and horizontally.

6.0ECNC-MS

| Specifications | UNIT | US | METRIC |

|---|---|---|---|

| Non-ferrous tubing (Yield to 25,000 PSI) | IN/MM | 6.000 X 0.375 | 150.0 X 9.5 |

| Steel tubing (Yield to 40,000 PSI) | IN/MM | 6.000 X 0.188 | 150.0 X 4.7 |

| Stainless steel tubing (Yield to 60,000 PSI) | IN/MM | 6.000 X 0.095 | 150.0 X 2.4 |

| Square steel tubing (Yield to 40,000 PSI) | IN/MM | 4.000 X 0.250 | 100.0 X 6.3 |

| Steel pipe | IPS | 5 IPS Sch 80 | |

| Solid steel bar | IN/MM | 3.500 | 88.9 |