HVAC

HVAC Tube Bending Applications

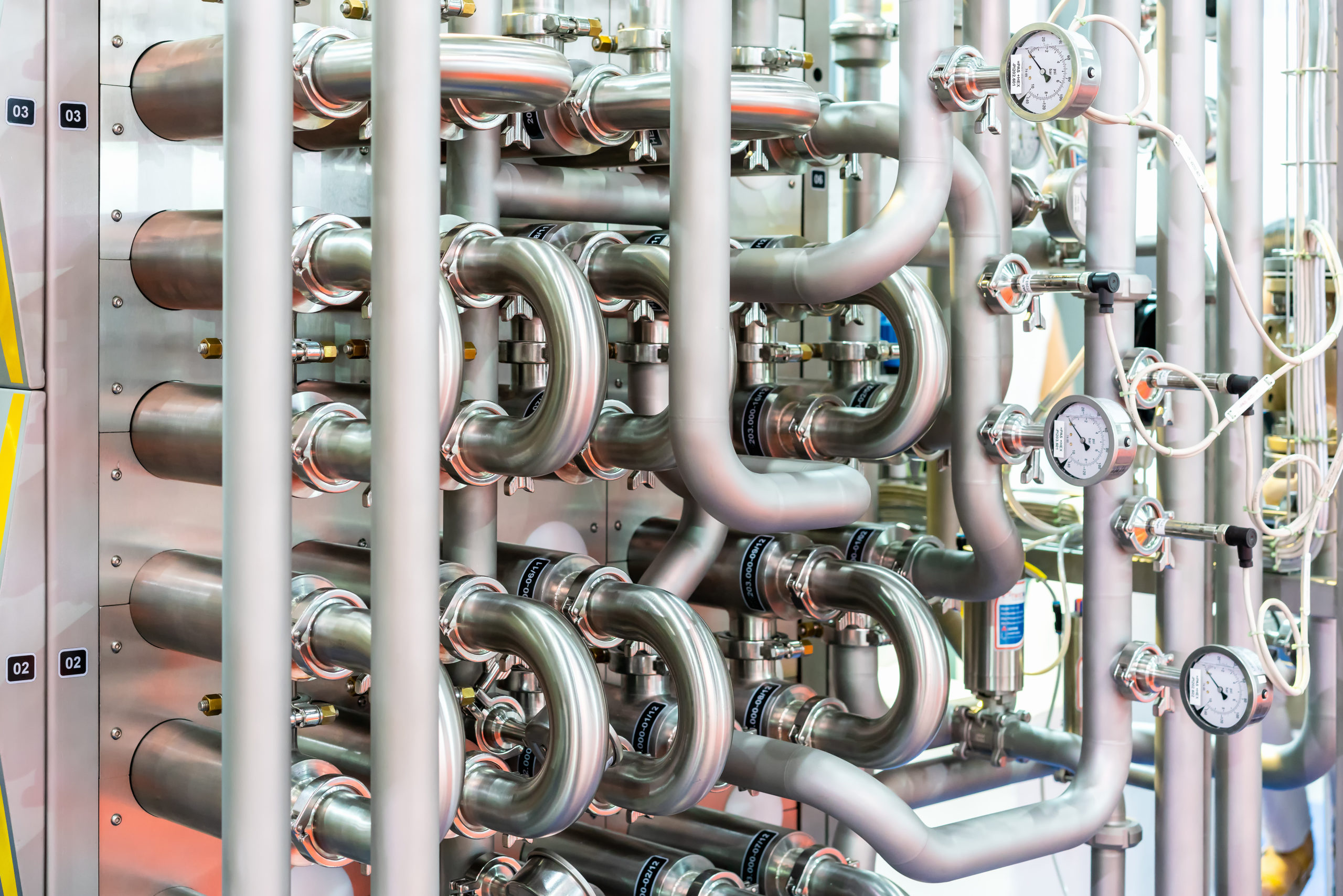

HVAC stands for Heating, Ventilation, and Air Conditioning. CNC tube benders are used to manufacture boiler circuits using thick wall tubing, and they are also used for bending thin wall copper in air handling applications. They are also used in specialty applications such as controlled wrinkle bending using thin wall stainless or aluminized steel. There are a lot of idiosyncrasies with the materials that are used in the HVAC industry, so experience in these industries is every bit as important as the performance of the tube bender and tooling required for these applciations.

CONTROLLED WRINKLE BENDING